WinSPC version 9.0.17 has been released and is now available for download. This release includes support for anonymous email connections for internal SMTP mail servers that require it.

WinSPC version 9.0.17 has been released and is now available for download. This release includes support for anonymous email connections for internal SMTP mail servers that require it.

WinSPC version 9.0.16 has been released and is now available for download. This release includes support for TLS 1.2 email connections and corrects issues when Dashboard charts pull from archives.

Statistical process control has far reaching impacts

WinSPC version 9.0.15 has been released and is now available for download.

We find that there are 3 common practices among companies who are effectively minimizing process variation. (1) Real-time monitoring of manufacturing with operator access to data. (2) Visualization of process output for operators and supervisors. (3) Investigation into problems and prioritization of improvement initiatives.

WinSPC offers intuitive Quality data entry and can capture independently from your CMMs, ERP and other sources.

Monitoring refers to keeping an eye on displays–charts, dashboards, stat summaries, and other visualizations–that update in real-time. Alarming refers to WinSPC’s real-time responses to violations–responses in the form of on-screen messages, audible sirens, priority e-mails, flashing indicators, or a number of other configurable reactions.

Together, real-time monitoring and real-time alarming form the core of real-time statistical process control.

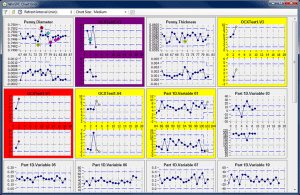

Processes are monitored through live on-screen updates. As data is captured, WinSPC generates charts and visualizations in real-time to show performance, identify violations, and summarize process health.

Processes are monitored through live on-screen updates. As data is captured, WinSPC generates charts and visualizations in real-time to show performance, identify violations, and summarize process health.

Two of WinSPC’s most popular displays are dashboards and data collection charts.

Dashboards are what supervisors and engineers typically rely on. They can include statistics, data grids, violation lists, and charts. They’re easy to configure and may be viewed on individual computers or large plant-floor displays.

Data collection charts are the charts shown in WinSPC’s data collection window. They are generally what operators who capture data look at and they too are quickly configured to suit particular requirements.

All the standard SPC charts are available for use in dashboards and the data collection window. So whether it is measurements (also known as variable data) that you monitor or observations from inspections (attribute data), WinSPC displays the statistically correct chart. Additionally, through the use of chart schemes, you can personalize a chart’s look-and-feel so it conveys its message, good or bad, in the most effective manner possible.

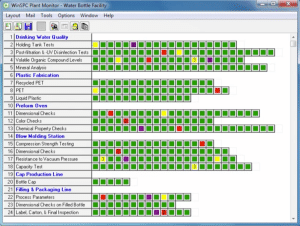

In addition to dashboards and data collection charts, WinSPC ships with the Plant Monitor, an easy-to-use tool that offers a plant-wide, color-coded view of operational status, empowering management to rapidly zero in on production issues and know exactly where to focus their attention.

In addition to dashboards and data collection charts, WinSPC ships with the Plant Monitor, an easy-to-use tool that offers a plant-wide, color-coded view of operational status, empowering management to rapidly zero in on production issues and know exactly where to focus their attention.

For more information on real-time monitoring, watch the Capturing Data and Generating Alarms and Monitoring and Analyzing with Dashboards videos.

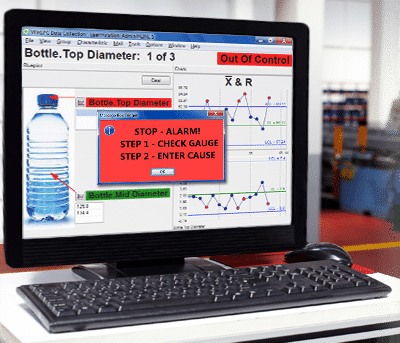

WinSPC’s real-time alarms eliminate guesswork. They tell shop-floor operators and supervisors when to take action and, equally important, when not to.  The moment a control limit, spec limit, SPC rule, or other condition is violated, a WinSPC alarm triggers and prompts shop-floor personnel to spring into action, correcting the condition that caused the violation, often before it results in scrap or rework–a direct contribution to the bottom line.

The moment a control limit, spec limit, SPC rule, or other condition is violated, a WinSPC alarm triggers and prompts shop-floor personnel to spring into action, correcting the condition that caused the violation, often before it results in scrap or rework–a direct contribution to the bottom line.

Some WinSPC alarms do more than just indicate when to take action. They indicate what action to take. An on-screen message, for example, or a priority e-mail details exactly what to do, ensuring that even a minor step doesn’t get overlooked.

Still other WinSPC alarms themselves take the actions to remedy a situation. In severe cases, they could adjust a setting on upstream equipment or shutdown a failing machine or launch another program—actions all designed to mitigate risk at the absolute earliest point in time.

All of WinSPC’s alarms can be configured in seconds and attached to industry-standard rules, such as the Western Electric set, as well as user-defined rules that detect less generic but still vital concerns.

For more information on WinSPC’s real-time alarming capability, watch the Capturing Data and Generating Alarms video.

An international leader in precision aerospace parts and components is feeling the effects of real-time predictive analysis software and loving the tenacious support team that backs it up.

A household name in the medical products industry is realizing incredible speed improvements and labor time savings with WinSPC.

Maybe the adage “if it’s not broken, don’t fix it” has given management an excuse not to change from old systems that do basic data entry and after-the-fact reporting.

Tightening a bakery’s operating efficiency and controlling weight variation down to a hundredth of an ounce are critical to product consistency and corporate profitability.

One international baker chose WinSPC real-time statistical process control software to deliver real-time feedback to line operators at the point of production.

Statistical Process Control is most effective when applied as close to the point of production as possible. Statistical Process Control charts have been called the Voice of the Process.

With WinSPC, one 70-year-old instrument manufacturer tracks production for traceability and analysis.

One North American textile company is delivering production problem forecasting to shift managers with WinSPC real-time statistical process control software.

A family run bread manufacturer is leveraging WinSPC real-time alerts to get a handle on overfill and underfill waste.

WinSPC version 9 is now in General Release and is available for all new and existing customers.

Living up to agreements with customers for acceptable quality levels (AQL) is a critical concern among manufacturers.

Timely feedback from a real-time SPC system is allowing one bread manufacturer to minimize production of non-complying snacks–a costly waste of raw ingredients, manpower, and machine energy.

Kick start or expand your WinSPC real-time statistical process control system by leveraging cloud technology to run WinSPC. Save the time spent time managing your own hardware/software setup.

The much anticipated WinSPC version 9 has entered Limited Release and will soon be available for public review.

DataNet now offers a new recorded, instructor-led training on Statistical Process Control basics, delivered by a senior SPC trainer.

WinSPC’s Cost Inspector™ can identify which process inefficiencies are costing manufacturing operations the most.

“Our objective is to supply easily accessible process information to further enhance our data driven decisions for continuous improvement of our manufacturing plant processes.”

Version 9 reflects an unprecedented effort to touch every aspect of the product in order to improve its ability to solve your problems, become easier to use and easier to own.

In this November Quality Magazine cover story, Frank Tappen retells his favorite Data Collection War Stories about the unpredictable human aspects of manufacturing.

WinSPC version 8.3.9 has been released and is now available for download. Customers with an active ESC (Extended Service Coverage) account are eligible to receive the new version.

Answers to some of the most frequently asked questions about IT involvement in a WinSPC installation are provided in the latest chapter of the WinSPC video tour.

Real-Time SPC delivers efficiency and productivity gains by eliminating manual data collection efforts, but its real power lies in the ability promote continuous improvement and identify out-of-control process parameters.

DataNet has expanded its WinSPC training in response to the growing demand for low-cost, personalized and on-demand educational options.

DataNet is excited to announce a partnership with Cdel IT of Buenos Aires, Argentina to provide complete WinSPC solutions for manufacturers seeking a capable local presence in Latin America.

A recognized leader in gum, mint and candy manufacturing, with products distributed throughout the globe, implements WinSPC to reduce costs while ensuring compliance with its high product quality standards.

DataNet’s preview of its newest product — WinSPC Envision — is now online.

DataNet unveils WinSPC Envision, a simple web-based WinSPC server monitoring and analysis tool, providing customers unparalleled access to their manufacturing network or supply chain from nearly any computing device.

WinSPC version 8.3.8 has been released and is now available for download. Customers with a active ESC (Extended Service Coverage) account are eligible to receive the new version.

Join us on LinkedIn and receive timely updates regarding the company and our products in addition to helpful tips from our team of experts.

You can use WinSPC’s trigger setup window to craft a corrective action message box with color significance and product-specific directives.

A contract manufacturer specializing in electromechanical and PCB assembly for high end laptop manufacturers and the Department of Defense implements WinSPC statistical process control software at two US based facilities.

DataNet has unveiled a web-based tour of WinSPC, with self-paced interactive simulations of software functionality and SPC solutions.

WinSPC version 8.3.7 has been released and is now available for download. Customers with an active ESC (Extended Service Coverage) account are eligible to receive the new version.

The need for round-the-clock process monitoring has increased as production schedules ramp up to meet global demand. Make sure you’re ready to continually match the competition with 24×7 Service Coverage.

What if adjusting a few machine settings could save you thousands or millions of dollars a year?

To provide executives and other leaders value, the data delivered to them has to be relevant and actionable.

DataNet Quality Systems has added MicroRidge’s line of wireless transmitters and hubs to its arsenal of hardware, software and services geared towards helping you achieve your quality goals.

With WinSPC real-time SPC software you can examine past production to improve your processes in 3 straightforward steps.

If you are trusting your process data to Excel, the time might be right for considering making the leap to an automated, real-time SPC solution.

WinSPC version 8.3.4 has been released and is now available for download. Customers with a active ESC (Extended Service Coverage) account are eligible to receive the new version.

“As a direct result of our rapid growth, we realized that we needed to upgrade our existing methods for managing statistical process control.”

DataNet Customers – you can now get additional training without leaving your facility! DataNet is hosting online training sessions tailored to your needs.

WinSPC real-time statistical process control software can help you to easily generate a COA report to clear regulatory requirements.

Don Elmore, Chief Software Architect at DataNet Quality Systems describes a tool for manufacturers to help them identify their ripest areas for financial improvement.

Today, I’ll share some of the recent benchmark data that helps to put into perspective why a focus on improving quality with SPC makes sense for many organizations in today’s economic environment.

Strong license sales of WinSPC statistical process control software indicates increasing demand for quality control automation from manufacturing executives.

DataNet now has a new group on LinkedIn for WinSPC users to discuss concerns with the software and become stronger users. They can discuss industry issues as well including topics led by DataNet.

In this video, you’ll see how to monitor a production facility using WinSPC. You’ll manage SPC rule violations across a plant and solve a production problem using WinSPC’s real-time Plant Monitor.

Using this new model, you can search for hidden areas of inefficiency and waste, analyze characteristics to identify the causes of that inefficiency, and justify quality initiatives by quantifying the amount of savings your company will realize with an improved process.

A worldwide manufacturer of filtration technologies installs WinSPC as its statistical process control system.

Global manufacturer of industrial and automotive rubber products selects WinSPC as its statistical process control system.

WinSPC version 8.3.0 has been released and is now available for download. Customers with an active ESC (Extended Service Coverage) account are eligible to receive the new version.

You can use filters in WinSPC real-time statistical process control software to zero in on the data you’re interested in and get help solving your critical Quality issues.

WinSPC version 8.2.1 has been released and is now available for download. Customers with an active ESC (Extended Service Coverage) account are eligible to receive the new version.

One of the world’s largest producers of folding cartons and a global leader in coated, recycled boxboard selects WinSPC as its corporate-wide statistical process control (SPC) system.

WinSPC reports can help you make a case for your Quality initiatives in statistical and financial terms.

Global leader in home, health, and beauty products selects WinSPC as its SPC software system for use across multiple operations.