Proper control chart selection is critical to realizing the benefits of Statistical Process Control.

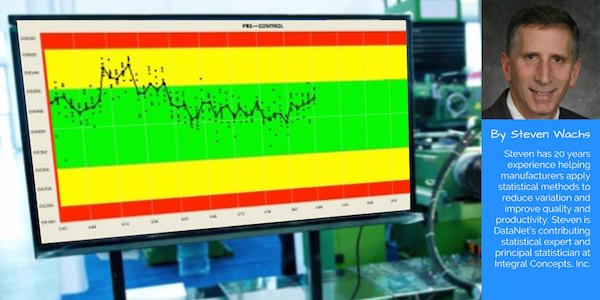

This is a crucial distinction that is frequently confused. Basically, specification limits have to do with the voice of the customer while control limits have to do with the voice of the process.

This is a crucial distinction that is frequently confused. Basically, specification limits have to do with the voice of the customer while control limits have to do with the voice of the process.

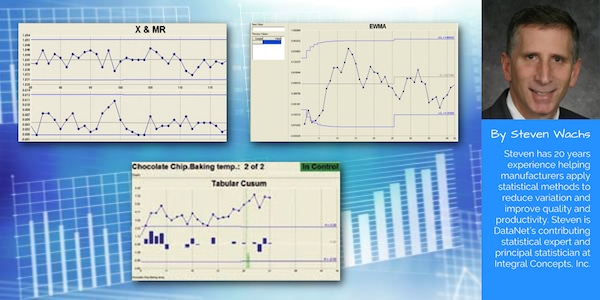

Proper control chart selection is critical to realizing the benefits of Statistical Process Control.

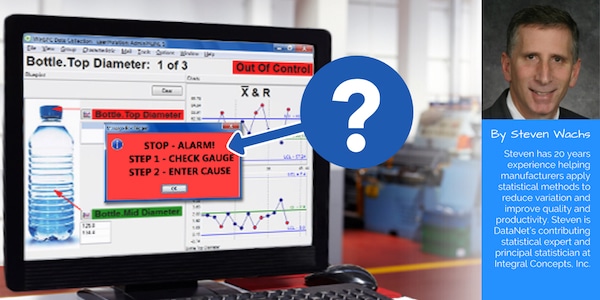

Many believe that an out of control process produces defective parts. That’s not always true.

When Statistical Process Control is applied properly, tremendous benefits in profitability and process understanding are achieved.

Unfortunately, applying “simple” tools at the expense of tools with considerably more value (and really not much more complexity or difficulty) doesn’t cut it.

The purpose of control charting is to regularly monitor a process so that significant process changes may be detected.