Monitoring and Alarming

Monitoring refers to keeping an eye on displays–charts, dashboards, stat summaries, and other visualizations–that update in real-time. Alarming refers to WinSPC’s real-time responses to violations–responses in the form of on-screen messages, audible sirens, priority e-mails, flashing indicators, or a number of other configurable reactions.

Together, real-time monitoring and real-time alarming form the core of real-time statistical process control.

Real-Time Monitoring

Processes are monitored through live on-screen updates. As data is captured, WinSPC generates charts and visualizations in real-time to show performance, identify violations, and summarize process health.

Processes are monitored through live on-screen updates. As data is captured, WinSPC generates charts and visualizations in real-time to show performance, identify violations, and summarize process health.

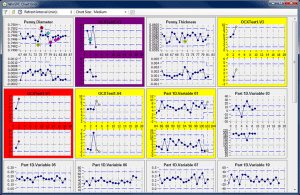

Two of WinSPC’s most popular displays are dashboards and data collection charts.

Dashboards are what supervisors and engineers typically rely on. They can include statistics, data grids, violation lists, and charts. They’re easy to configure and may be viewed on individual computers or large plant-floor displays.

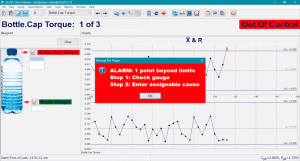

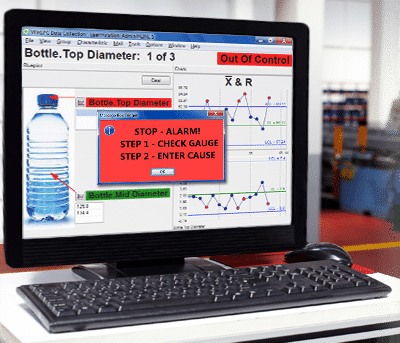

Data collection charts are the charts shown in WinSPC’s data collection window. They are generally what operators who capture data look at and they too are quickly configured to suit particular requirements.

All the standard SPC charts are available for use in dashboards and the data collection window. So whether it is measurements (also known as variable data) that you monitor or observations from inspections (attribute data), WinSPC displays the statistically correct chart. Additionally, through the use of chart schemes, you can personalize a chart’s look-and-feel so it conveys its message, good or bad, in the most effective manner possible.

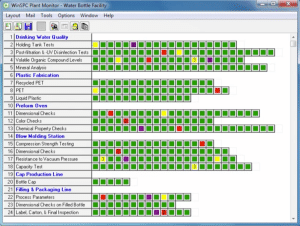

In addition to dashboards and data collection charts, WinSPC ships with the Plant Monitor, an easy-to-use tool that offers a plant-wide, color-coded view of operational status, empowering management to rapidly zero in on production issues and know exactly where to focus their attention.

In addition to dashboards and data collection charts, WinSPC ships with the Plant Monitor, an easy-to-use tool that offers a plant-wide, color-coded view of operational status, empowering management to rapidly zero in on production issues and know exactly where to focus their attention.

For more information on real-time monitoring, watch the Capturing Data and Generating Alarms and Monitoring and Analyzing with Dashboards videos.

Real-Time Alarming

WinSPC’s real-time alarms eliminate guesswork. They tell shop-floor operators and supervisors when to take action and, equally important, when not to.  The moment a control limit, spec limit, SPC rule, or other condition is violated, a WinSPC alarm triggers and prompts shop-floor personnel to spring into action, correcting the condition that caused the violation, often before it results in scrap or rework–a direct contribution to the bottom line.

The moment a control limit, spec limit, SPC rule, or other condition is violated, a WinSPC alarm triggers and prompts shop-floor personnel to spring into action, correcting the condition that caused the violation, often before it results in scrap or rework–a direct contribution to the bottom line.

Some WinSPC alarms do more than just indicate when to take action. They indicate what action to take. An on-screen message, for example, or a priority e-mail details exactly what to do, ensuring that even a minor step doesn’t get overlooked.

Still other WinSPC alarms themselves take the actions to remedy a situation. In severe cases, they could adjust a setting on upstream equipment or shutdown a failing machine or launch another program—actions all designed to mitigate risk at the absolute earliest point in time.

All of WinSPC’s alarms can be configured in seconds and attached to industry-standard rules, such as the Western Electric set, as well as user-defined rules that detect less generic but still vital concerns.

For more information on WinSPC’s real-time alarming capability, watch the Capturing Data and Generating Alarms video.