WinSPC

WinSPC is software to help manufacturers optimize their processes, the end goal of which is the ultimate goal of all manufacturers–the highest quality products for the lowest possible cost. Firmly rooted in the science of SPC, WinSPC facilitates real-time statistical process control, in-depth analysis for process improvement, reporting to meet a diverse range of information needs, and automated compliance with regulatory requirements.

…many manufacturers believe that they understand their performance until confronted with real data.

Helu & Hedberg, NIST

It’s easy to implement, easy to learn, and, perhaps most importantly, very easy to administer–with many tasks being able to be done in a single mouseclick.

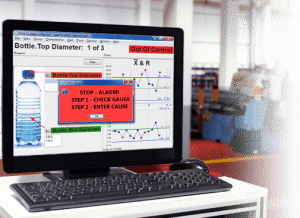

WinSPC is installed on shop-floor computers where it is ideally positioned to capture data from virtually any source–serial devices, text files, Excel files, machines, gauges, enterprise databases and systems, and keyboards. As data is

captured, it is immediately displayed, allowing shop-floor personnel to monitor processes in real-time. Simultaneously, the data is tested against SPC rules and process-specific requirements. When one or more of these is violated, alarms are instantly triggered–alarms in the form of on-screen messages, audible sirens, priority e-mails, flashing indicators, or a number of other configurable actions. The real-time control these capabilities bring about can add millions to a company’s bottom line. Additional information is available on our Capture Data and Monitoring and Alarming pages as well as in the Capturing Data and Generating Alarms or Monitoring and Analyzing with Dashboards videos.

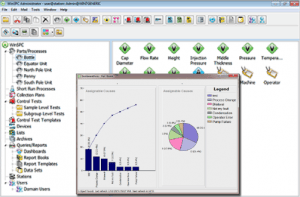

Additionally, WinSPC offers analysis capabilities that enable Quality teams to go beyond just controlling processes into new levels of process improvement.  Engineers can search, filter, drill-down, and sort until they’ve isolated the data that needs to be investigated. They can, in a couple of mouseclicks, subject an operation’s historical data to a battery of statistical studies. They can even setup WinSPC to constantly be on the lookout for risks specific to their zones of responsibility. The tools WinSPC gives analysts result in statistically sound actionable intelligence capable of improving processes to heights previously thought unattainable. For more information on WinSPC’s analysis capabilities see the Analysis and Reporting page or the Monitoring and Analyzing with Dashboards video.

Engineers can search, filter, drill-down, and sort until they’ve isolated the data that needs to be investigated. They can, in a couple of mouseclicks, subject an operation’s historical data to a battery of statistical studies. They can even setup WinSPC to constantly be on the lookout for risks specific to their zones of responsibility. The tools WinSPC gives analysts result in statistically sound actionable intelligence capable of improving processes to heights previously thought unattainable. For more information on WinSPC’s analysis capabilities see the Analysis and Reporting page or the Monitoring and Analyzing with Dashboards video.

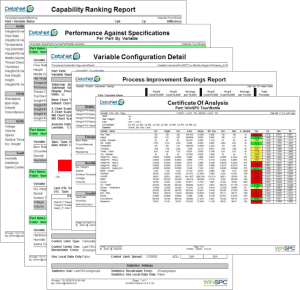

As for reporting, manufacturers have many information needs–needs of executives, engineers, suppliers, customers, upstream and downstream operations, and supervisors. WinSPC’s out-of-the-box report templates, which number over 90, cover all the key areas: Quality, production, cost, and more. Each is professionally formatted and can generate a report with just a few clicks of the mouse. The knowledge shared through WinSPC reports makes for a team that is united and focused on common goals.

As for reporting, manufacturers have many information needs–needs of executives, engineers, suppliers, customers, upstream and downstream operations, and supervisors. WinSPC’s out-of-the-box report templates, which number over 90, cover all the key areas: Quality, production, cost, and more. Each is professionally formatted and can generate a report with just a few clicks of the mouse. The knowledge shared through WinSPC reports makes for a team that is united and focused on common goals.

For more details on this topic, see the Analysis and Reporting page or watch the Generating Reports video.

To get an overview on how WinSPC automates regulatory compliance for companies in regulated industries, see the Achieve Regulatory Compliance page.

Click here for a printable WinSPC brochure.

Recommendations for Collecting, Curating, and Re-Using Manufacturing Data – NIST