American tool manufacturer uses WinSPC to tighten its grip on excellence

A prominent hand tool manufacturer, based in the midwest, forges and machines bar stock steel rods into high-quality handheld tools.

Background

Working jointly with professional tradespeople, the company constantly looked for ways to reconceive decades-old tools, striving for maximum user productivity. And their efforts paid off in features that give tool users new and unique experiences, setting a new standard for the skilled trades.

Automated Operations

Up from the corn fields in a rural midwestern town has emerged a brand new manufacturing facility, within which extensive automation is employed.

Up from the corn fields in a rural midwestern town has emerged a brand new manufacturing facility, within which extensive automation is employed.

Spearheading this are Makino cells with multiple nests–the very cutting edge of robotic machining.

Manufacturing hands-on tools, it turns out, is greatly aided by hands-off automation.

Futuristic SPC and Quality

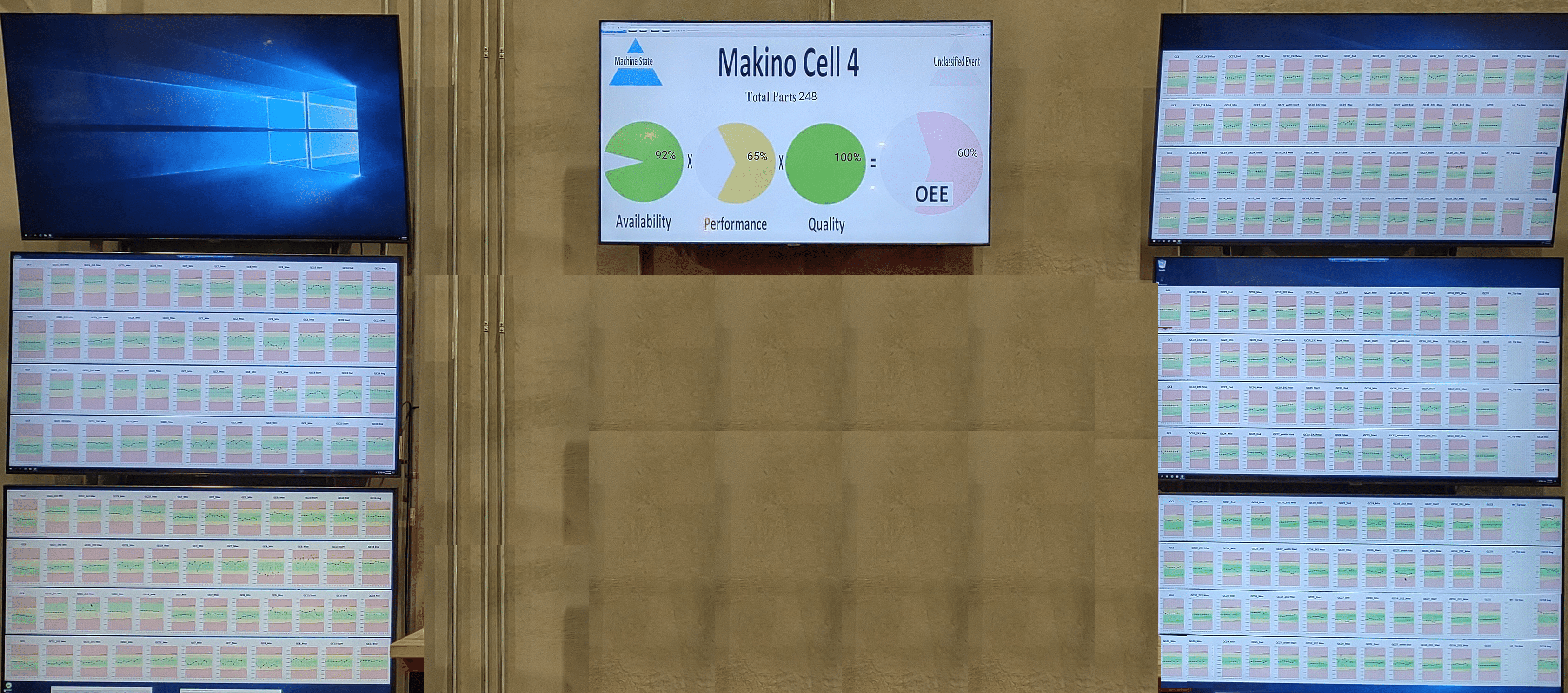

From a quality perspective, the approach on the new shop floor shows the future of SPC enablement and quality improvement. Sixty-five-inch monitors, 6 in all, are given prime real estate, creating a veritable home theater for quality data.

Each monitor is visible from the Makino machines and displays operation-specific dashboards with SPC charts that refresh every few minutes, ensuring critical-to-quality information is always in front of whoever needs it. WinSPC is the software the manufacturer selected to generate those charts.

Although the sheer size and number of these monitors is a testament to the importance of the data they present, it is ultimately people that make the difference. Knowing this, it was decided early on to educate every production employee on basic SPC concepts and support them with specialized experts in quality. Operators are trained to keep one eye on their processes and the other on the corresponding WinSPC charts, looking for non-optimum trends and alarm conditions, so they can intervene quickly. When warranted, they directly update the charts with notes, assignable causes, and corrective actions, serving both institutional learning and audit trail needs.

Unique to this facility, because of its newness, is that many of its processes are being done for the first time, as are therefore the projects to continuously improve them. Quality methods and procedures are rigorously tested and refined. In some cases, this involves doing the maximum number checks at a high frequency until capability is clearly proven and only then reducing inspections. The success of the site’s methods and procedures is attributed to the fact that SPC was enshrined on day one of production as the driving force for monitoring and controlling operations.

When manufacturing is humming here, defects are rare. But, when they occur, given that hundreds of units are produced per hour, they become costly if they aren’t addressed promptly. Consequently, the company is committed to the use of WinSPC’s statistically calculated control limits. These clearly expose variation and immediately indicate when a process has gone out of control and is at risk of violating specification limits, a high-expense event. Because of WinSPC’s control tests and alarms, out-of-control but not yet out-of-spec processes can be given high-priority attention by technicians. When they can resolve the issue on the fly, they do, before spec-limit violations occur. When they can’t, they halt the machine and investigate until they can, again before spec-limit violations occur. Reliance on control limits as opposed to spec limits, the company understands, is the reason they achieve higher quality at lower cost.

Outcomes

As a result of their commitment to SPC and quality, they have, impressively, already been able to document corrective actions based on events that predict outcomes. Their processes have become more stable over time and operators better understand how different machines perform at different settings as well as how tool wear influences quality.

Equally impressive is the passion and craftsmanship of the manufacturer’s employees, one of which said this about his day-to-day experiences with WinSPC:

Equally impressive is the passion and craftsmanship of the manufacturer’s employees, one of which said this about his day-to-day experiences with WinSPC:

“WinSPC has been an awesome tool to help predict when something is going wrong, and more than that, it tells you multiple things about how the machine is running in a single view, like which tool is having an issue and causing burrs on the parts that needs to be addressed immediately. I don’t know what we would do without it. People are caring more about overall quality. SPC drives improvements in the bottom line. Over time, SPC charts tell the story that the techs can’t see if they are just looking at raw data (from the CMM), and we can watch for issues that may have started to happen on previous shifts. Those key machine performance details are communicated from shift to shift and are shown clearly on the SPC charts.”

Engineers are also monitoring individual tools, as they may move between machines over multiple months. They are starting to see trends on specific part dimensions due to a particular tool that is trending out of control and now they take the necessary action to prevent parts from going out of spec. Again, according to the same employee: “There is an incredible amount of data and the system (WinSPC) does a good job providing live updates.”

Even more, the business is now generating capability statistics, including Cpk, that are reported to the management team on a regular basis. First in the reports is the number of quality characteristics that have a Cpk less than 1.0 and are at risk of lower quality. Second is the count of characteristics that may need attention with a Cpk landing between 1.0 and 1.3. Third is the most common and most gratifying count, characteristics with a Cpk greater than 1.3, proudly proving capability as a reward for untiring efforts.

We have all heard that one of the overarching goals of SPC is to prevent defects and scrap before additional and expensive manufacturing steps occur on parts in production. This midwestern company earns high marks for making this a reality day-in and day-out by having built the culture and quality mindset from the ground up.